Amid COVID-19 Pandemic, Cal Poly Engineering Faculty Members Adapt Courses, Shift Focus to Coronavirus

Multiple faculty members in the spring quarter will encourage their students to help with ventilator shortages, design medical products, and publish analysis of biological data related to worldwide health crisis

As soon as Eric Paton heard there was a shortage of hospital ventilators worldwide amid the ongoing COVID-19 outbreak, the Cal Poly lecturer reached out to students he knew could help and designed a course to address the challenge.

“I heard that medical staff in Italy were removing ventilators from older patients, sedating them to die and giving the ventilators to younger patients,” said Paton, who teaches in both the industrial and manufacturing, and materials engineering departments at Cal Poly. “This broke my heart.”

As faculty rush to craft lesson plans on how to teach the upcoming spring quarter’s classes virtually amid ongoing shelter-at-home and social distancing orders, many College of Engineering professors are adapting even further — changing their curriculum to address the very coronavirus pandemic that is forcing the switch from classrooms to exclusively virtual teaching.

“We were originally going to have the students design a product to help the sight impaired,” said Karla Carichner, whose biomedical engineering design class will now focus on creating products related to coronavirus. “Given our current circumstances, this seems more relevant.”

“While the pandemic has altered our daily lives and exposed the vulnerabilities of health care worldwide, engineers are in a unique position to help medical professionals treat the afflicted," said College of Engineering Dean Amy S. Fleischer.

“Engineers are trained to quickly adapt to rapid change and to fix problems. And at Cal Poly, we pride ourselves on doing meaningful work that can improve quality of life. So it should be no surprise that our faculty and students are not only adjusting to a new way of educating but also addressing a worldwide crisis while doing it.”

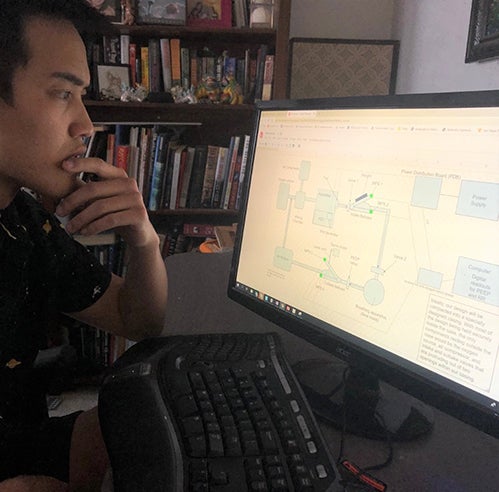

Paul Anderson, associate professor in the Computer Science and Software Engineering Department, has experience teaching online courses, and one of his interests is bioinformatics — the science of collecting and analyzing complex biological data, such as genetic codes. He saw the opportunity to alter his bioinformatic algorithm course this spring to focus on studying the virus and comparing it to other viruses and diseases.

“We’ll be studying various molecular, genomic, genetic and evolutionary aspects of the novel coronavirus from an algorithmic point of view,” he said.

While the virus provides a timely topic to study in class, faculty and students will join the scientific community at large in seeking solutions.

A ventilator machine provides precious air to those unable to breathe on their own by pumping air into their lungs through a tube inserted into their windpipes. Because COVID-19 affects the respiratory system, the number of hospitalized patients in need of breathing assistance has risen exponentially since the pandemic began, resulting in a startling lack of ventilators worldwide. This prompted the Italian Critical Care Society to approve the extreme idea of offering younger patients priority, saying doctors should “privilege greater life expectancy.”

With the American Hospital Association projecting that 960,000 U.S. residents will need ventilator support because of the virus, the U.S. Department of Defense reached out to the scientific community to come up with possible solutions — on a tight deadline — to develop a low-cost mechanical ventilation support system that can be rapidly reproduced at a local level. Paton quickly submitted ideas and invited three students to do the same.

“Engineers turn ideas into reality,” Paton said. “This is where the rubber meets the road. We need to act now.”

Cameron Wong, a mechanical engineering student who took on the challenge, said undergraduates like him can offer a fresh perspective.

“We are not as familiar with the formal engineering and design process,” Wong said, “and therefore look at the problem from a completely different perspective and can offer much more creative solutions that professionals in the field may not have considered.”

Meanwhile, Paton’s materials engineering class will team with iFixit, a San Luis Obispo company whose wiki-based website teaches people how to fix almost anything, to create technical manuals for ventilators. While existing machines are breaking down because of heavy use, technical manuals offering repair information are often difficult to find. Paton’s class of 70 students will target ventilators that are most needed and create technical manuals that provide step-by-step instruction on iFixit.

Similar to Paton’s class, Carichner’s biomedical engineering class will break into teams, which will generate product designs for different challenges. The ideas that result could entail improving existing products or new ones.

“I would expect it to range from something hospitals could use to devices that limit contact to products that help in isolation,” she Carichner, a lecturer who also teaches in the materials and industrial engineering departments.

Combating coronavirus is a collaborative effort. So sharing information will be important.

“Due to the nature of the threat facing us as a society, we will also prioritize delivering high-quality analysis and synthesis of the output of our algorithms for the public,” Anderson said. “We’ll be pulling down data from scientists around the world and integrating it into class as soon as it’s available.”

While others will likely have done the same work, Anderson said, Cal Poly students will approach it differently and have more time to make the analysis available.

“I also believe that everyone should do everything in their power to help during this pandemic, and this is a way I can help my students feel like they are part of a larger community,” he said.